Project Overview

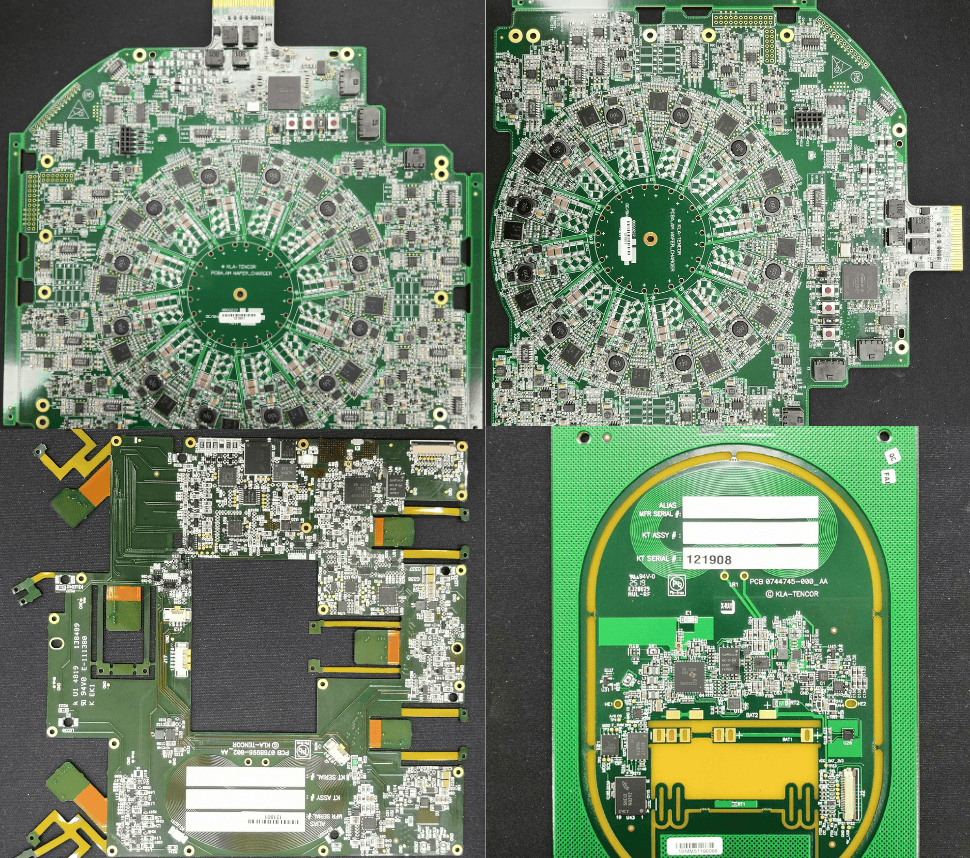

KLA requires complex electronic circuits for inspection and control systems used in semiconductor manufacturing processes. These circuits include rigid and flexible boards in specialized configurations, integrating precise electronic and mechanical solutions for high-resolution, high-speed data acquisition, processing, and analysis.

Implementation Strategy

Michmas Electronics implemented a comprehensive solution combining rigid, flex, and ultra-flex PCB layout and manufacturing. The cards were designed (layout designed) to accommodate specific mechanical constraints, necessitating custom mounting and connection solutions. From component procurement through PCB production and final assembly, the project required advanced coordination and high-mix flexibility. Each production batch included dozens of units across multiple configurations, addressing the diverse range of KLA-Tencor’s system needs.

Outcome

Michmas successfully produced multiple PCB batches tailored to the stringent standards of the semiconductor industry. Our ability to handle complex mechanical and electronic requirements ensured seamless integration into KLA-Tencor’s systems. This collaboration has continued over time, with Michmas consistently supporting product innovation cycles and quality assurance across the client’s next-gen testing machines.